Currently, technology is transforming the field of industrial manufacturing in unprecedented ways. The rapidly evolving metal processing and manufacturing industry has gained recognition and attention from numerous enterprises, playing a crucial role in today's socio-economic development. In the face of the promising powder metallurgy market, both OEM (Original Equipment Manufacturer) and independently developed production companies aspire to carve out a slice of the "big cake" of powder metallurgy. Regardless of how fierce the competition may be and how the market evolves, what still earns customer trust are companies with extensive industry experience, technological advantages, and product quality that surpasses their peers.

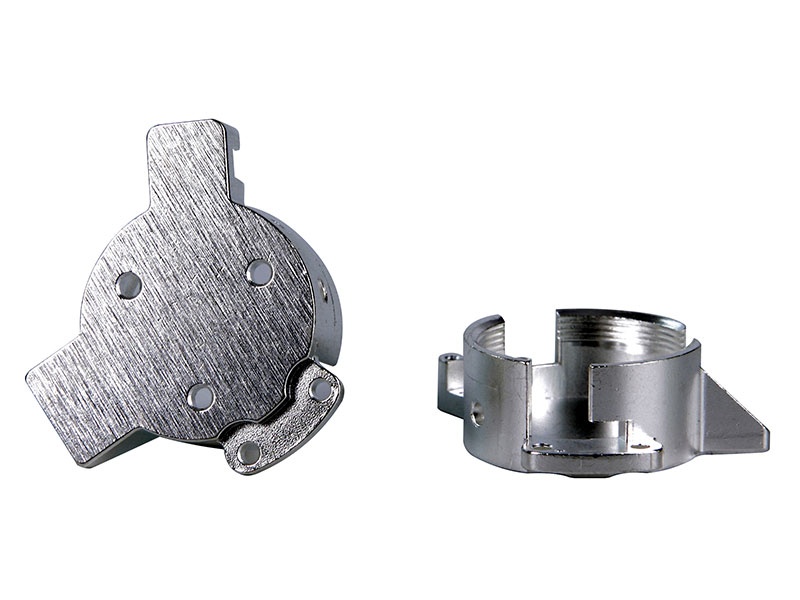

Powder Metallurgy Metal Parts

As a high-tech enterprise engaged in powder metallurgy PM and MIM (Metal Injection Molding) process production and processing, Harber MIM has developed into the preferred powder metallurgy manufacturer in the market, known for its advanced production equipment, metallurgical expertise, comprehensive service processes, and exceptional quality.

Harber MIM possesses advanced molding and sintering equipment, including imported equipment from Germany, ensuring precision in powder metallurgy components and consistency in batch production. Furthermore, Harber MIM boasts a professional technical team, advanced MIM injection molding technology, PM compression molding technology, and years of research and application experience in powder metallurgy, which serve as the cornerstone for maintaining the quality of metallurgical products.

In the field of powder metallurgy, Harber MIM has independently developed over 5,000 varieties of products, encompassing precision parts, oil-impregnated bearings, structural components, gears, stainless steel powder metallurgy components, and various powder injection molded products widely used in sectors such as automotive, hardware tools, consumer electronics, medical devices, and base station communications. Presently, Harber MIM is recognized as a pioneer in the domestic powder metallurgy industry.

Leading technological transformation in the industry and continuously expanding the application market for metallurgical products have been the long-term commitments of Harber MIM. The new future of industry has already begun, with high-performance, high-precision metal components becoming the new challenge for various enterprises in the powder metallurgy field. In the future, Harber MIM will keep pace with the development of the times, continuously strive for progress and innovation, align with market needs, focus on research and development, provide comprehensive technical services, and offer metallurgical solutions for key cooperative enterprises, empowering the high-precision development of industrial manufacturing companies and contributing to intelligent manufacturing in China.