metal injection molding electronic component part

Brand name | OEM & ODM |

Product type | Adjustable hinge mim part |

Product Model | MIM702 |

Material | Stainless steel 316L 304 17-4PH peptide Fe2Ni Fe4Ni Fe20Ni |

Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

Size | Custom |

Tolerance | 10mm±(0.02-0.04)mm |

Weight | 10g |

Forming Method | Powder Injection Molding |

Sintering method | Solid phase sintering |

Sintering environment | Vacuum |

Mold material | Stainless steel |

Application | Security industry |

Shape | Custom |

OEM | Accept |

QC system | 100% inspection before shipment |

Payment terms | T/T at sight, Paypal, Western Union,etc. |

Lead time | 7-15 working days |

Supply capability | 500000 Piece Per Month |

Packaging | PP bag / Anti-static film / anti-static plastic disc |

MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc.

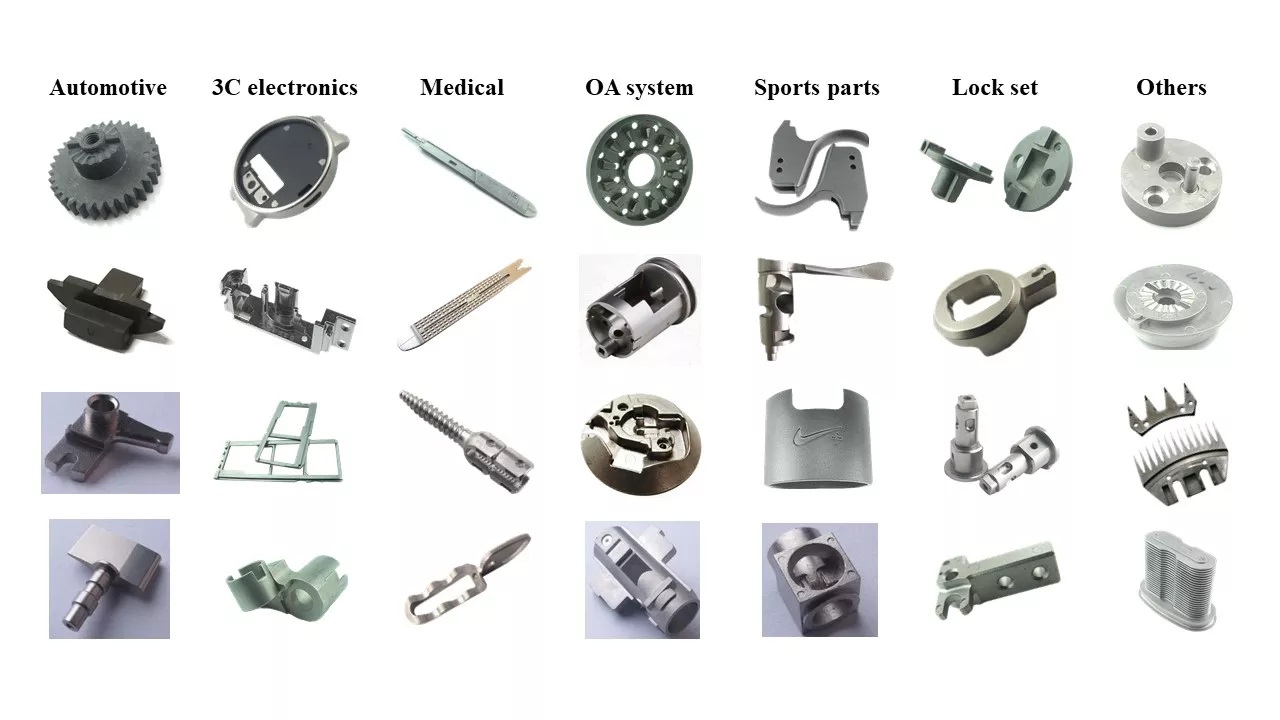

Main materials and applications for MIM:

Properties of MIM materials