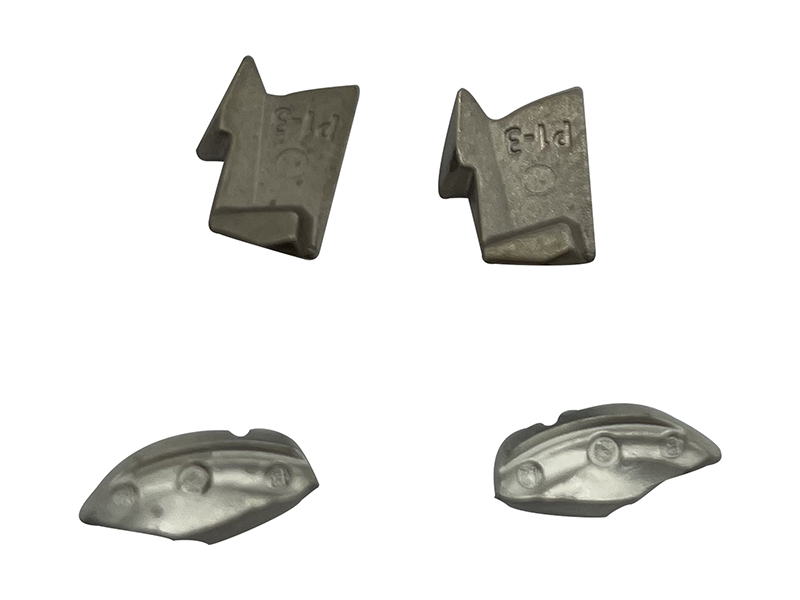

metal injection molding electronic component mim sim card part

Brand name | OEM & ODM |

Product type | Adjustable hinge mim part |

Product Model | MIM702 |

Material | Stainless steel 316L 304 17-4PH peptide Fe2Ni Fe4Ni Fe20Ni |

Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

Size | Custom |

Tolerance | 10mm±(0.02-0.04)mm |

Weight | 10g |

Forming Method | Powder Injection Molding |

Sintering method | Solid phase sintering |

Sintering environment | Vacuum |

Mold material | Stainless steel |

Application | Security industry |

Shape | Custom |

OEM | Accept |

QC system | 100% inspection before shipment |

Payment terms | T/T at sight, Paypal, Western Union,etc. |

Lead time | 7-15 working days |

Supply capability | 500000 Piece Per Month |

Packaging | PP bag / Anti-static film / anti-static plastic disc |

MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc.

Main materials and applications for MIM

Applicable materials

The MIM process is applicable to a wide range of materials, including low alloy steel, stainless steel, tool steel, nickel-based alloys, tungsten alloys, cemented carbide, titanium alloys, magnetic materials, Kovar alloys, etc.

Table 1 Commonly used PIM materials and their application fields:

Material classification | Material grade | Application areas |

Iron-based alloy | Fe-2Ni, Fe-8Ni 310 | Various structural parts in automobile, machinery and other industries |

Stainless steel | 316L ,17-4PH, 420, 440C | Medical equipment, watch parts |

Carbide | WC-Co | Various knives, clocks and watches |

ceramics | Al2O3, ZrO2, SiO2 | IT electronics, daily necessities, watches and clocks |

heavy alloy | W-Ni-Fe, W-Ni-Cu, W-Cu | Communications, daily necessities |

Titanium alloy | Ti,Ti-6Al-4V | Medical, aviation |

magnetic materials | Fe, Fe50Ni, Fe-Si | Various magnetic performance parts |

tool steel | 42CrMo4,M2 | various tools |

copper alloy | —— | Conduct heat and electricity |

Table 2 Properties of several typical PIM materials:

MaterialMaterial | density | hardness | Tensile Strength | Elongation | |

g/cm 3 | Lowe's | MPa | % | ||

Iron-based alloy | PIM-2200 (sintered) | 7.60 | 45HRB | 290 | 40 |

PIM-2700 (sintered) | 7.60 | 69HRB | 440 | 26 | |

PIM-4605 (sintered state) | 7.60 | 62HRB | 415 | 15 | |

PIM-4605 (quenching, tempering) | 7.60 | 48HRC | 1655 | 2 | |

Stainless steel | PIM-316L (sintered) | 7.85 | 67HB | 520 | 50 |

PIM-17-4PH (sintered) | 7.5 | 27HRC | 900 | 6 | |

PIM-17-4PH (sintered) | 7.5 | 40HRC | 1185 | 6 | |

PIM - 440C (sintered) | 7.5 | 65HRB | 415 | 25 | |

Tungsten alloy | 95%W-Ni-Fe | 18.1 | 30 | 960 | 25 |

97%W-Ni-Fe | 18.5 | 33 | 940 | 15 | |

fine ceramics | Al2O3 | 3.9 | HRA92 | Bending strength | - |

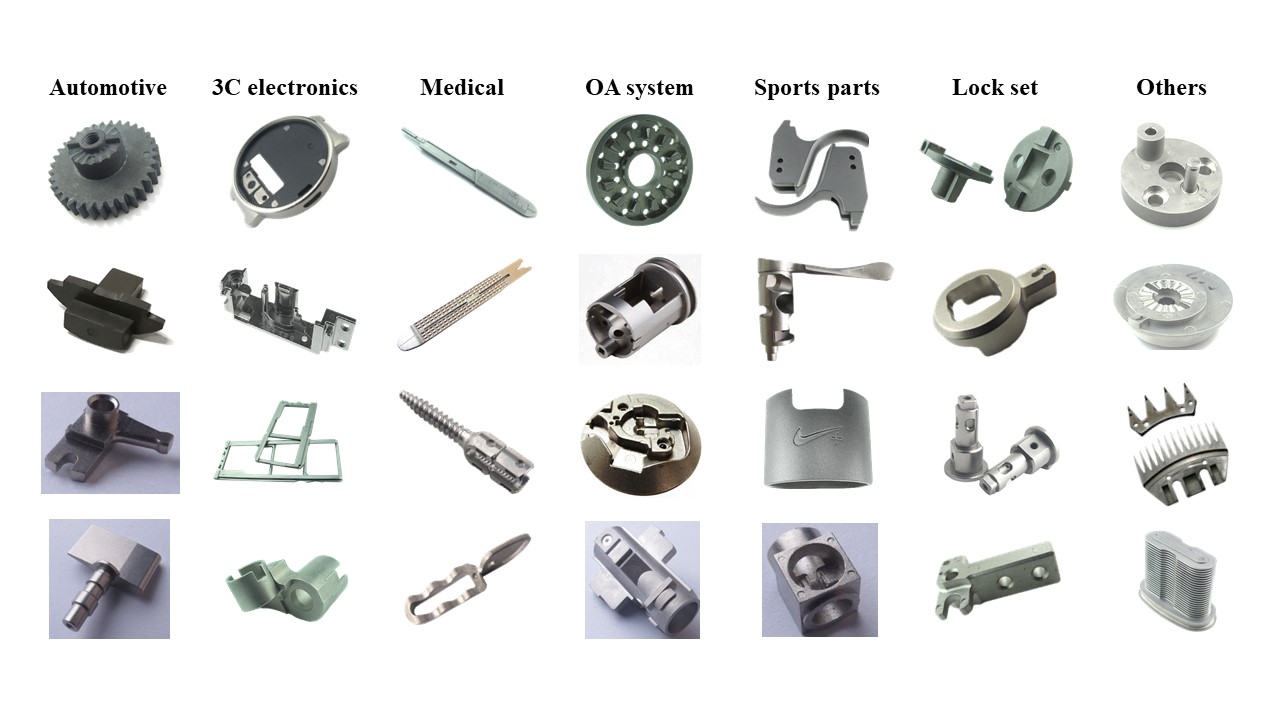

Application of MIM Common Products