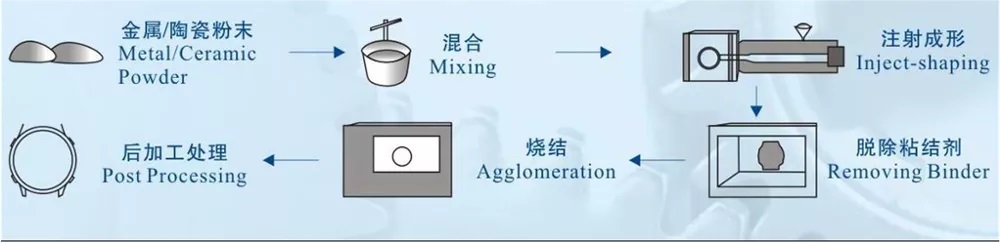

How does MIM work?

1.Can dlrectly produce complicated component

with the final shape and size, such as asymmetric components, components with groove,cross hole, blind hole,components with huae chanae in wall thickness, components with pattern and character on surface, etc.

2.Superlor product performance

Since the MiM product has the evenly microstructure and no rouah crystalline structure and composition segregation occured in casting process, they are obviously superiorer than the precision casting and traditional powder metallurgy materials in high densitystrength,hardness, high elongation and other mechanical properties good wear resistance, fatique resistance, uniform organization, etc.

3.lt can achleve the Integration of components

Due to the machining technologyand material property, some components are manufactured by adapting traditional techniques which sometimes needs to be machined into several parts to assemble and sometimes is different in the material of several parts.Using the MIM technology can directly made a whole composite parts.

4.Wlde range of materlals adaptablllty.

Any materials that are suitable for making into powder can be useful for producing parts by adapting MIM technology

5.Low production cost.

This can be showed in several parts:reducing or even eliminating CNC Machining, low labor intensity, increase production efficiency; rawmaterial utilization rate is high, avoiding waste in cutting, high automation of production line, simple production process and continuous mass production, etc.

metal injection molding electronic component part

Brand name | OEM & ODM |

Product type | Adjustable hinge mim part |

Product Model | MIM702 |

Material | Stainless steel 316L 304 17-4PH peptide Fe2Ni Fe4Ni Fe20Ni |

Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

Size | Custom |

Tolerance | 10mm±(0.02-0.04)mm |

Weight | 10g |

Forming Method | Powder Injection Molding |

Sintering method | Solid phase sintering |

Sintering environment | Vacuum |

Mold material | Stainless steel |

Application | Security industry |

Shape | Custom |

OEM | Accept |

QC system | 100% inspection before shipment |

Payment terms | T/T at sight, Paypal, Western Union,etc. |

Lead time | 7-15 working days |

Supply capability | 500000 Piece Per Month |

Packaging | PP bag / Anti-static film / anti-static plastic disc |

MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc.

Main materials and applications for MIM:

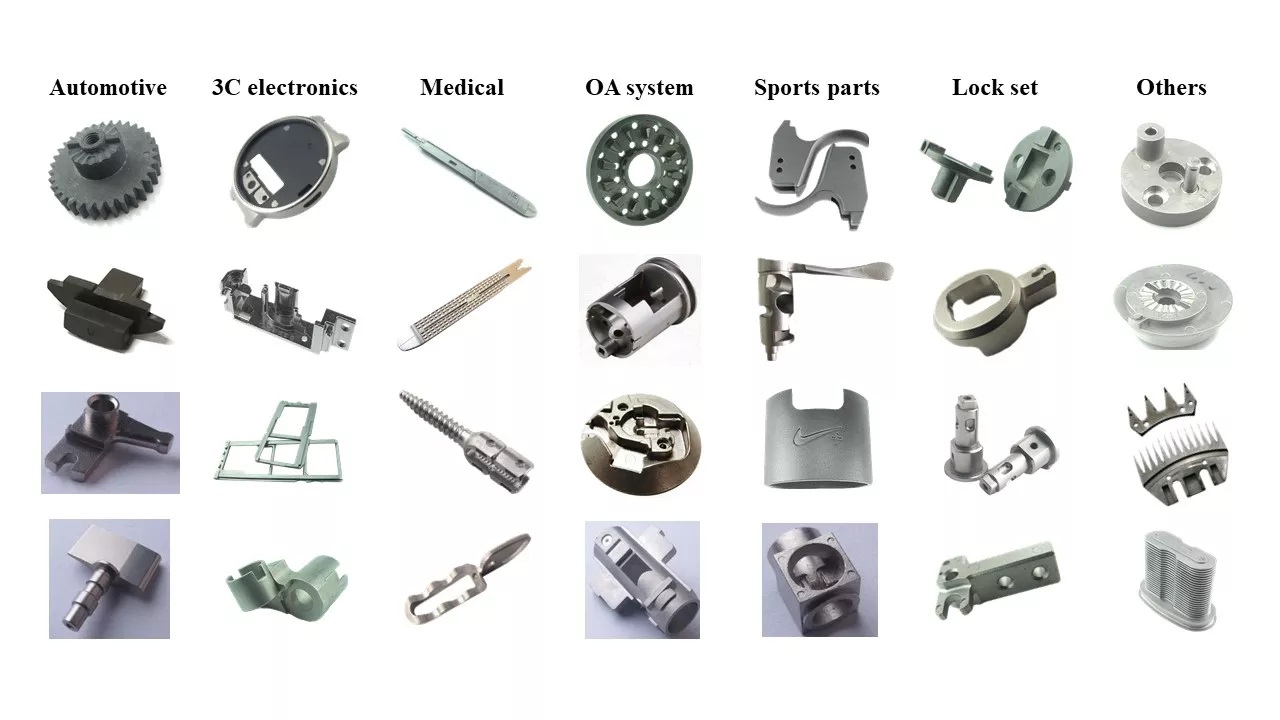

Application of MIM Common Products