Project Time: March 2022

Industry: Minimally Invasive Surgery

Material used: Titanium Alloy & Ceramic

Qty: 100000pcs mim parts

Client Introduce: Listed as a Fortune 500 companies, the company is one of the world's leading medical technology companies offering a diverse array of innovative products and services in Orthopaedics, Medical, Surgical, Neurotechnology and Spine that help improve patient and hospital outcomes.

Case background

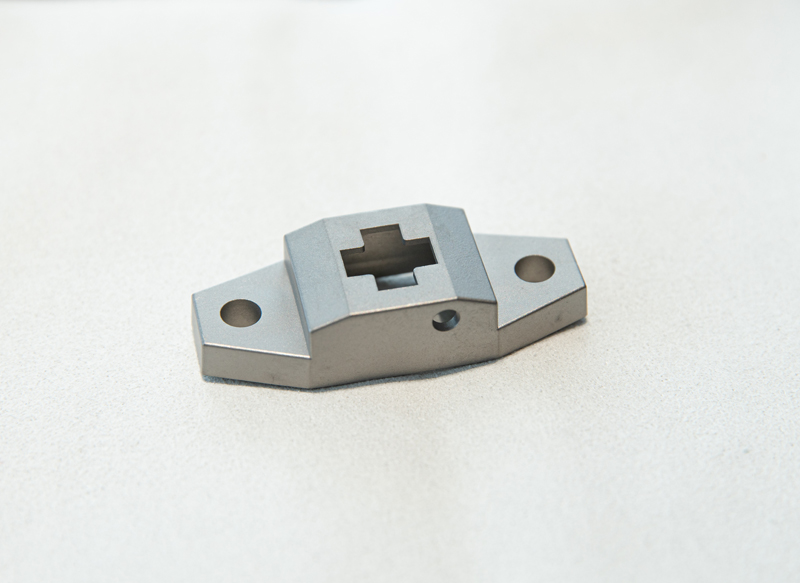

This is a part that one of our China inland customers needs to customize. The customer is the top hardware assembly manufacturer in China, and has strict quality requirements. The material needed to be highly magnetic and corrosion resistant, hence the part had to go through various processes like surface coating electroless zinc nickel alloy. This part used FeSi3(Fe3%Si) with high physical properties with 53mm*29mm*18mm, weight 12.4g. Harber MIM delivery the ripe experiences and solution.

Solution

Harber MIM was the best place for the above-mentioned manufacturer. The requirement was close tolerances, which was an area of excellence for HARBER MIM. Thus, we developed a custom-made magnetic material FeSi3 for the product as per the manufacturers’ specifications.After sintering, the surface hardness is about 10HRC, which is the best degree we do post process- reshaping. And surface coating zinc-nickle alloy is also difficult process, we have rich experiences to make surface balance. Harber MIM also have a professional tooling factory and team,also created a Multi Cavity Tool, which helped to meet their high volume requirements.