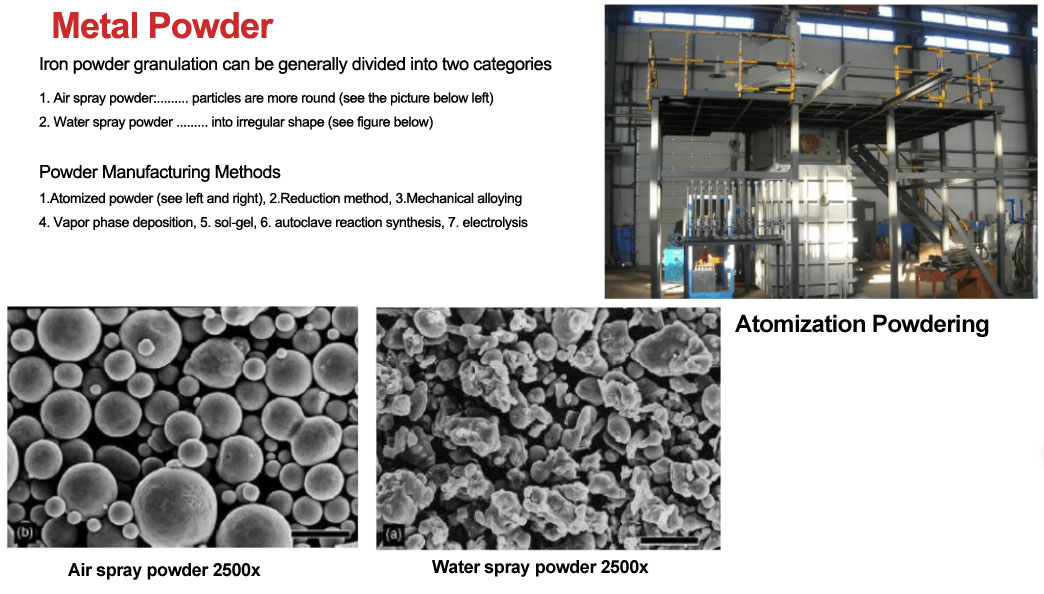

Metal injection molding (MIM) is a manufacturing solution that allows for production of intricate parts in medium to high volumes (10,000 to over 2,000,000 parts annually), using fine (<20 µm) metal powders. MIM is capable of transforming complex concepts and designs into the mass production for high precision and net-shape products.

MIM excels at applications that require shape complexity and superior properties such as high strength, excellent magnetic permeability, good creep resistance, corrosion resistance and thermal conductivity. Harber’s material portfolio includes a wide range of materials such as carbon steels, low alloy steels, stainless steels, low thermal expansion alloys, non-ferrous metals like tungsten and copper, super alloys like inconel, F75, MP35N and Nimonic 90.

Combining our MIM technology, material innovations and engineering expertise over the past 10 years, Harber is able to offer innovative solutions such as bi-material integration, thin-wall capability, etc. Find out more about these innovative MIM applications here.

MIM technology is most ideally used for high-volume production, Harber focus to serve in the medical industry. MIM technology is ideal for mass producing components used in robotic surgical systems. These robotic surgical systems typically have end-effectors such as clamps, graspers, staplers, needle holders, etc, which are of very complex geometries and shapes.

One-stop Metal Solutions

Haber understands our partners’ frustration in managing multiple vendors. As your strategic manufacturing partner, Haber is able to provide one-stop solutions in:

Design For Manufacturability (DFM) Concept

Mold Flow Simulation Study

Prototyping (3D Metal Printing/Additive Manufacturing) Services

Validation and Qualification Protocol

In-house CNC Machining Capability

On Time Delivery Mass Production

Customized Testing and Inspection

Manage reliable local and overseas vendors with areas of expertise in:

CNC Machining - grinding, turning lapping, etc

Heat treatment - H900 profile, case hardening, full hardening, etc

Plating which - EN, nickel, gold, silver, etc

Finishing - passivation, electro-polishing, glass beading, sand blasting, etc

Providing assembly services in white room or clean room

Using automation and robotic systems to improve production efficien

The mim metal production technologies discussed above, as well as CNC machining metal fabrication, are available on Harber's online manufacturing platform.

Get an instant quote for metal parts

Get an instant quote by uploading your CAD files to https://www.harbermetal.com/Instant-Quote/.

There you can specify your products material, surface finish, threaded holes, tolerances and lead time. You can also confirm manufacturability using our instant DfM feedback.

Supported file types:

.step, .stp, .iges, .x_t, .x_b, .sldrpt, .ipt, .3dxml, .prt, .sat, .cgr, .3dm, .catpart, .scad (max file size: 250 MB)

All uploads are secure and confidential.

Additional resources

To learn more about photo etching, CNC machining, and other digital manufacturing technologies, check out this collection of articles and guides to help you delve deeper: